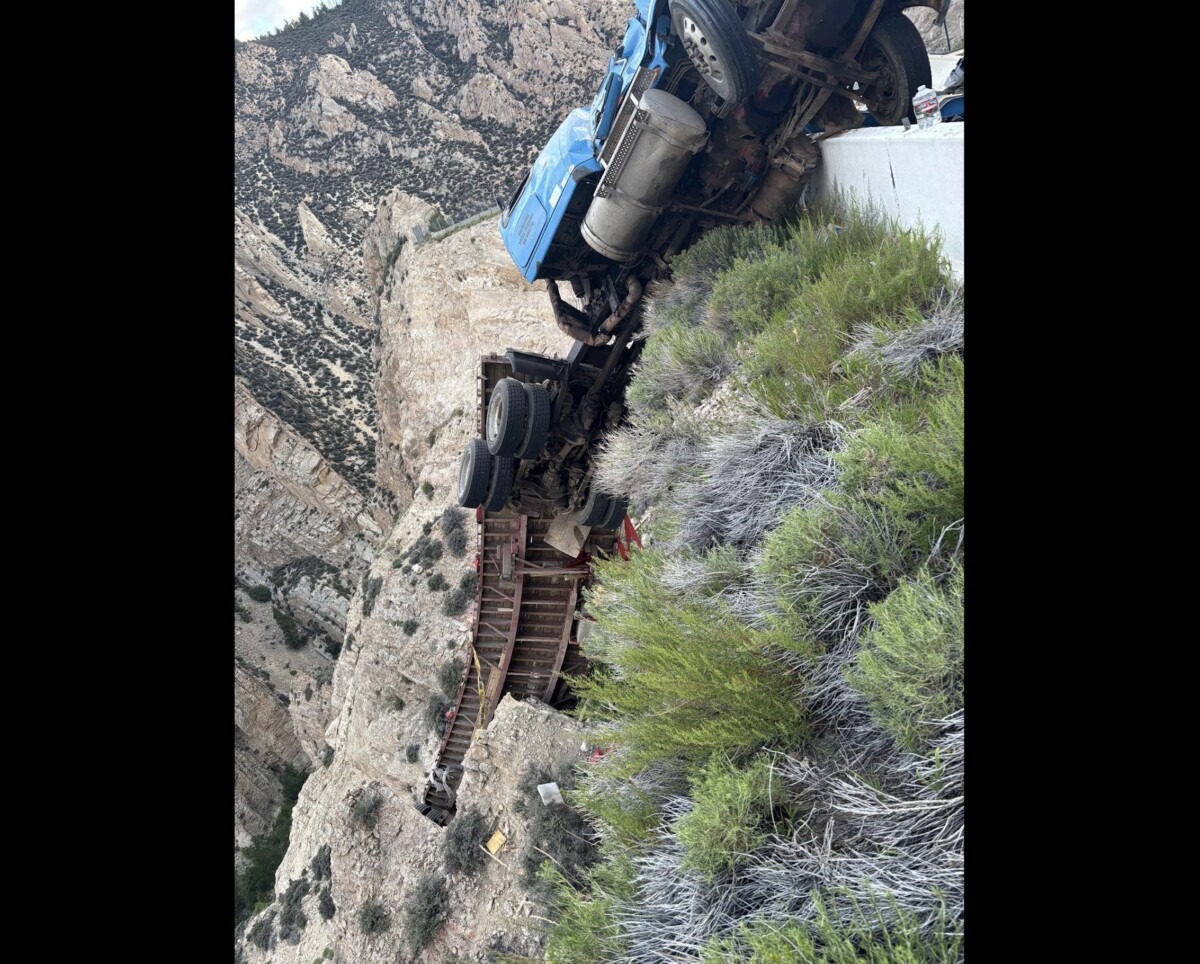

A liquid hydrogen fuel tank on Daimler’s GenH2 truck. (Daimler Truck)

ANAHEIM, Calif. — Affordable and available hydrogen is critical to large-scale adoption of fuel cell systems and internal combustion engines that use the fuel, but it’s up to manufacturers and fuel producers to develop solutions and help address the economic and operational hurdles fleets confront with hydrogen fueling infrastructure, experts said at ACT Expo.

“For hydrogen, we had a megalomaniac view that we were going to have a national strategy and hubs and billions of dollars in funding … I think we are at a point where we are getting a bit of a reality check,” said Abhinav Kumar, project manager for Linde Engineering.

Equipment manufacturers said they are closely watching infrastructure developments.

“In this chicken and egg situation, we have a lot at stake here,” said Ted Haladyna, director of product marketing for Ford Pro in North America. Ford is pursuing hydrogen solutions in the Class 3 to 5 space.

Finding fueling infrastructure — and then ensuring the truck can do the job — are equally vital.

“You may have a great truck, but it is held back by the infrastructure,” said Joachim Ladra, head of sales, marketing and communication for Cellcentric, a joint venture between Daimler Truck AG and the Volvo Group. “The truck has to fulfill its job. If that doesn’t happen, it isn’t good for the operator, whether the truck or the infrastructure is the issue.”

RELATED: Alternative Fuels ‘Back on the Menu’ at ACT Expo

The attractiveness of fuel cell and hydrogen internal combustion engines will also hinge on the fuel’s price per kilogram. “You have to be competitive, or people will choose diesel,” said Robert Wegeng, president and chief technology officer of Stars Technology Corp., a Richland, Wash.-based company that is commercializing compact hydrogen production systems.

Kumar noted that Linde has more than 200 active stations worldwide and is currently building a hydrogen refueling station near its production facility in La Porte, Texas. By locating the refueling site near the point of production, Linde can move hydrogen from its production facility to the refueling station via a short pipeline run. “When we do that, we don’t have to worry about liquification and trucking,” he said.

Laura Parkan, senior vice president, commercial management, large industries and hydrogen for Air Liquide North America, noted that value chain optimization, collaboration and economies of scale can help drive down costs. “Certainly, we have some projects that we’re working on where larger scale is helping affect lowering of cost,” Parkan said.

Wegeng said Stars Technology is managing costs by distributing units off of the natural gas grid, reducing transportation costs. The company recently completed a two-year demonstration of a clean hydrogen production pilot plant at the SunLine Transit Agency that used renewable natural gas to produce clean hydrogen for fuel cell buses.

Another company, called TO Viridi, has developed a system to isolate hydrogen from ethanol using a thermo-catalytic reaction.

RELATED: Cummins CEO Says Alternative Fuels Will Advance

While speaking to a group of journalists, Michael Lewison, president of TO Viridi, said the system, called HyEn+, has a 40-foot by 8-foot footprint and allows users to store ethanol instead of hydrogen. It can be located wherever it is needed and produce 1,250 kilograms of hydrogen a day at the fueling location while sequestering CO2, he said. The company is reviewing options for disposing of the carbon, including burying it, turning it into graphite for batteries and using it in concrete. He noted that ethanol can be distributed via current infrastructure, a benefit when compared to the lack of infrastructure for transporting hydrogen.

“Diesel and gasoline and our existing infrastructure is everywhere. The problem is that pollutes too much, so we’ve got to find a way to put them together,” Lewison said. “We believe, and we are proving, that bioethanol rises to feed these challenges, because ethanol [is] the third most abundant fuel on the planet, after gas and diesel.” Lewison foresees HyEn+ being used in behind-the-fence mobile applications. “We are ready to commercialize now and negotiating with multiple governmental and commercial entities,” he said.

Seth Clevenger and Mike Senatore dive into the Transport Topics Top 100 list of the largest logistics companies. They address trade challenges, mergers, sector trends and more. Tune in above or by going to RoadSigns.ttnews.com.

During a panel discussion on hydrogen production, Parkan said Air Liquide is rolling out an advanced delivery system developed from auto thermal reforming technology, which she said produces low-carbon hydrogen but has high carbon capture rates. She noted the company also has another carbon capture technology called Cryocap.

“Because we have both of those technologies, we can provide a hydrogen solution that delivers carbon capture rates of more than 99% at a cost-effective rate,” she said.

RELATED: Hyundai Unwraps Xcient Tractor Overhaul

Sarah Farnand, manager for hydrogen for mobility business development for Air Products, assured attendees that hydrogen is available and reliable. Air Products has 100 hydrogen production facilities and has placed mobile fuelers in the Edmonton, Canada, area.

Although producers are moving forward with new solutions, Farnand said it would be helpful if there was more certainty — and, ultimately, more customers in the market.

“We’d like to see better clarity on the demand side,” she said.